Deep Groove Ball Bearings

Deep Groove Ball Bearings

Dimensions Chart of Aligning Ball Bearings

Dimensions Chart of Aligning Ball Bearings

Dimensions Chart of Thrust Ball Bearings

Dimensions Chart of Thrust Ball Bearings

Dimensions Chart of Angular Contact Ball Bearings

Dimensions Chart of Angular Contact Ball Bearings

Dimensions Chart of Double-direction Angular Contact Ball Bearings

Dimensions Chart of Double-direction Angular Contact Ball Bearings

Dimensions chart of Cylindrical Roller Bearings

Dimensions chart of Cylindrical Roller Bearings

Dimensions chart of Tapered Roller Bearings

Dimensions chart of Tapered Roller Bearings

Dimensions chart of Tapered Thrust Bearings

Dimensions chart of Tapered Thrust Bearings

Dimensions chart of Spherical Roller Bearings

Dimensions chart of Spherical Roller Bearings

Dimensions Chart of Needle Roller Bearings

Dimensions Chart of Needle Roller Bearings

Size chart of High Speed Electric Spindle

Size chart of High Speed Electric Spindle

Size chart of Slewing Bearings

Size chart of Slewing Bearings

Dimensions chart of Bearing Units

Dimensions chart of Bearing Units

Dimensions chart of Ball Bearing Units

Dimensions chart of Ball Bearing Units

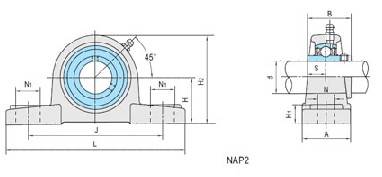

Pillow block housing with set screw

Pillow block housing with set screw

Pillow block housing with set screw

Pillow block housing with set screw

Pillow block housing with eccentric locking collar

Pillow block housing with eccentric locking collar

Pillow block housing with adapter sleeve

Pillow block housing with adapter sleeve

Pillow block housing with eccentric locking collar

Pillow block housing with eccentric locking collar

Pillow block housing (low center) with eccentric locking collar

Pillow block housing (low center) with eccentric locking collar

Pillow block housing (low center) with set screw

Pillow block housing (low center) with set screw

Pillow block housing (light load) with eccentric locking collar

Pillow block housing (light load) with eccentric locking collar

Pillow block housing (light load) with set screw

Pillow block housing (light load) with set screw

Small based pillow block housing with set screw

Small based pillow block housing with set screw

Pillow block housing (high center) with set screw

Pillow block housing (high center) with set screw

Four bolt flange housing with set screw

Four bolt flange housing with set screw

Four bolt flange housing with set screw

Four bolt flange housing with set screw

Four bolt flange housing with adapter sleeve

Four bolt flange housing with adapter sleeve

Four bolt flange housing with eccentric locking collar

Four bolt flange housing with eccentric locking collar

Four bolt flange housing with eccentric locking collar

Four bolt flange housing with eccentric locking collar

Two bolt flange housing with set screw

Two bolt flange housing with set screw

Two bolt flange housing with set screw

Two bolt flange housing with set screw

Two bolt flange housing with adapter sleeve

Two bolt flange housing with adapter sleeve

Two bolt flange housing with eccentric locking collar

Two bolt flange housing with eccentric locking collar

Two bolt flange housing with eccentric locking collar

Two bolt flange housing with eccentric locking collar

Take up flange housing with set screw

Take up flange housing with set screw

Take up flange housing with adapter sleeve

Take up flange housing with adapter sleeve

Pressed steel housing with two bolt flange

Pressed steel housing with two bolt flange

Pressed steel housing with two bolt flange

Pressed steel housing with two bolt flange

Pressed steel housing with two bolt flange

Pressed steel housing with two bolt flange

Pressed steel housing with two bolt flange

Pressed steel housing with two bolt flange

Pressed steel housing with two bolt flange

Pressed steel housing with two bolt flange

Pressed steel housing with two bolt flange

Pressed steel housing with two bolt flange

Pressed steel housing with two bolt flange

Pressed steel housing with two bolt flange

Pressed steel housing with two bolt flange

Pressed steel housing with two bolt flange

Pressed steel housing with two bolt flange

Pressed steel housing with two bolt flange

Pressed steel housing with two bolt flange

Pressed steel housing with two bolt flange

Pressed steel housing with two bolt flange

Pressed steel housing with two bolt flange

Pressed steel housing with two bolt flange

Pressed steel housing with two bolt flange

Pressed steel housing with two bolt flange

Pressed steel housing with two bolt flange

Pressed two bolt flange housing with eccentric locking collar

Pressed two bolt flange housing with eccentric locking collar

Pressed two bolt flange housing with set screw

Pressed two bolt flange housing with set screw

Address:No.88-10 Meixing Road, Baoshan District, Shanghai, China. P.C. 201901

Contacts:Jorge Chen

Tel:021-31300090

Fax:021-65655008

E-mall:sales@bembearing.com