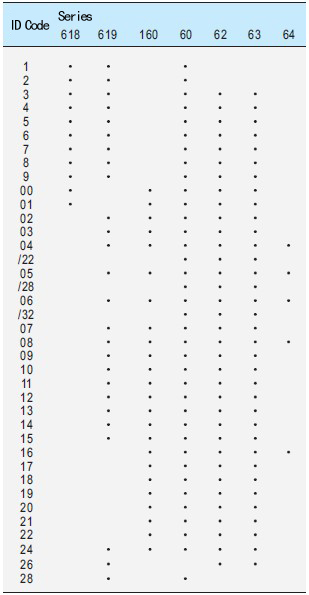

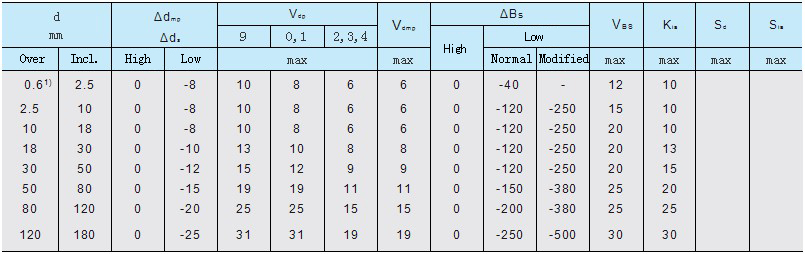

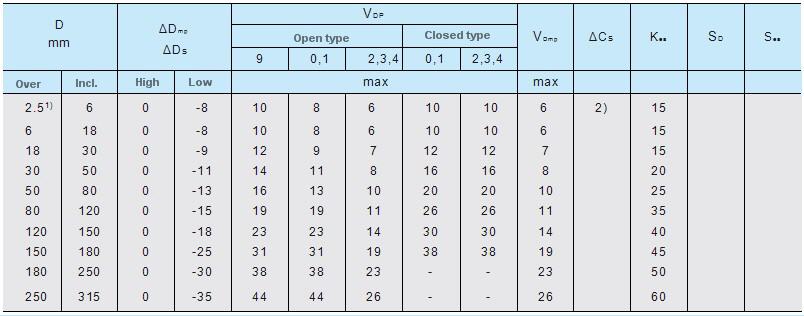

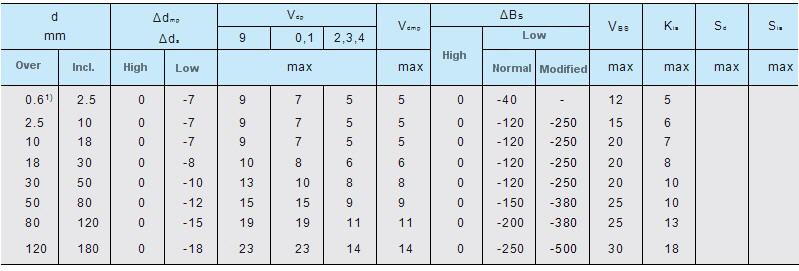

Deep Groove Ball Bearings

Deep Groove Ball Bearings

Dimensions Chart of Aligning Ball Bearings

Dimensions Chart of Aligning Ball Bearings

Dimensions Chart of Thrust Ball Bearings

Dimensions Chart of Thrust Ball Bearings

Dimensions Chart of Angular Contact Ball Bearings

Dimensions Chart of Angular Contact Ball Bearings

Dimensions Chart of Double-direction Angular Contact Ball Bearings

Dimensions Chart of Double-direction Angular Contact Ball Bearings

Dimensions chart of Cylindrical Roller Bearings

Dimensions chart of Cylindrical Roller Bearings

Dimensions chart of Tapered Roller Bearings

Dimensions chart of Tapered Roller Bearings

Dimensions chart of Tapered Thrust Bearings

Dimensions chart of Tapered Thrust Bearings

Dimensions chart of Spherical Roller Bearings

Dimensions chart of Spherical Roller Bearings

Dimensions Chart of Needle Roller Bearings

Dimensions Chart of Needle Roller Bearings

Size chart of High Speed Electric Spindle

Size chart of High Speed Electric Spindle

Size chart of Slewing Bearings

Size chart of Slewing Bearings

Dimensions chart of Bearing Units

Dimensions chart of Bearing Units

Dimensions chart of Ball Bearing Units

Dimensions chart of Ball Bearing Units

Grinding Electric Spindle

Grinding Electric Spindle

Grinding Electric Spindle

Grinding Electric Spindle

Machining Center and Parallel Machine Tool Electric Spindle

Machining Center and Parallel Machine Tool Electric Spindle

Machining Center and Parallel Machine Tool Electric Spindle

Machining Center and Parallel Machine Tool Electric Spindle

Milling Electric Spindle

Milling Electric Spindle

Milling Electric Spindle

Milling Electric Spindle

Milling and Cutting Machine Electric Spindle

Milling and Cutting Machine Electric Spindle

Machining Center Speed-increasing Head Electric Spindle

Machining Center Speed-increasing Head Electric Spindle

NC Drilling and NC Milling Electric Spindle

NC Drilling and NC Milling Electric Spindle

NC Drilling and NC Milling Electric Spindle

NC Drilling and NC Milling Electric Spindle

High-speed Centrifuge Electric Spindle

High-speed Centrifuge Electric Spindle

Turning Electric Spindle

Turning Electric Spindle

Rotation-rolling Electric Spindle

Rotation-rolling Electric Spindle

Special-purpose Electric Spindle

Special-purpose Electric Spindle

Machining Center Machinery Electric Spindle

Machining Center Machinery Electric Spindle

Woodworking Engraving and Milling Belt Spindle

Woodworking Engraving and Milling Belt Spindle

Address:No.88-10 Meixing Road, Baoshan District, Shanghai, China. P.C. 201901

Contacts:Jorge Chen

Tel:021-31300090

Fax:021-65655008

E-mall:sales@bembearing.com